Contact us

Tel:0574-86810961

Fax:0574-86810960

- Exhibition

- Intruduction

- Parameter

- case

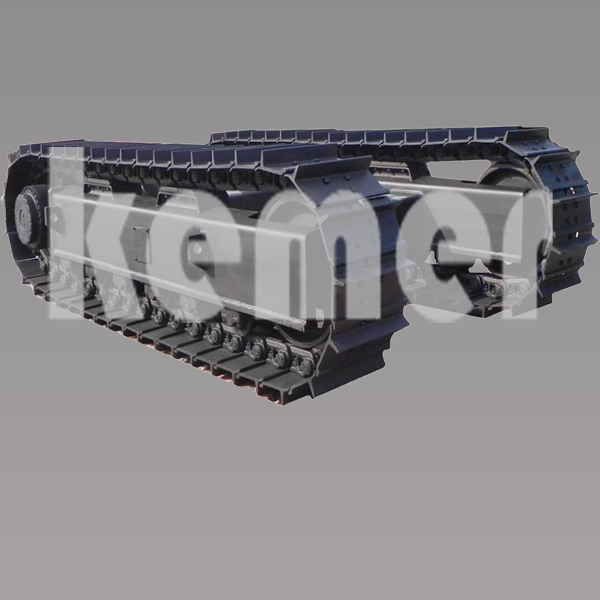

1.Definition

The crawler chassis is an important part of a machine, and has effects of supporting and running the whole device. It is composed of a running motor, a crawler assembly, a running frame, a driving wheel, a guide wheel, a supporting wheel, a bearing chain wheel, a tensioning mechanism and other parts, features high power, low ground pressure and good passing ability, and is widely applied to excavators, drilling machines, crawler cranes, crawler loaders, tunneling machines, harvesters and so on.

2. Features

1) Integrated two-speed or compact plunger hydraulic motor and reducer are adopted, and the driver features small volume, large traction, low energy consumption and so on; and the running motor and pipelines can be buried in a crawler to prevent damage caused by rough roads. A parking brake and a balance valve are arranged in the running motor to ensure stable running and stopping and reliable braking.

2) An all-welded heavy-load running frame is adopted, and crawler frames on two sides are rigidly welded with an intermediate beam.

3) The supporting wheel, the bearing chain wheel and the guide wheel are sealed by floating oil seals to ensure that lubricating oil does not need to be added during long-term work.

4) A standard grease tensioning cylinder and a spring with a shock absorber make the crawler more easily adjusted.

5) A durable crawler cage ensures that a track chain is not derailed (optional).

6) Lubricating grease lubricates a crawler sealing piece, so the insides of crawler chain link pins and pin bushes are more wear-resistant; and a crawler link adopts a ram-type production mode, so the joint of the crawler is firmer and more durable. A crawler link adopts a ram-type production mode, so the joint of the crawler is firmer and more durable.

7) A crawler plate made of high-strength alloy steel can bear external shock generated when the machine runs on rough ground and works on wet ground.

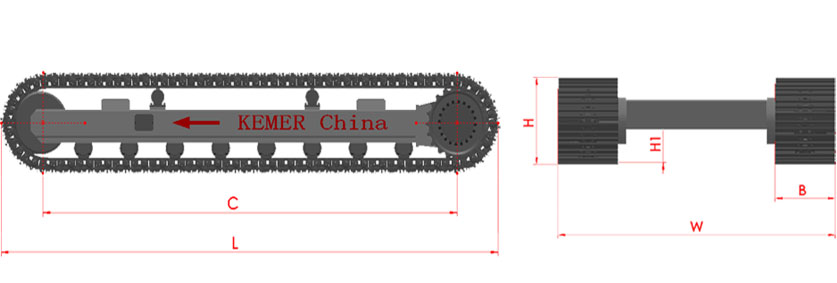

| Model | L | C | H | W | B | H1 | Suppo-rting wheel | Dynamic bearing capacity (kg) | Static bearing capacity (kg) | Self weight chassis (kg) | Ratio | Motor disspla-cement (ml/r) | Motor disspla cement (bar) | Motor flow (L/min) | Motor torque (N.m) | Climb-ing ability |

Runn-ing speed (km/h) |

| ST-5 | 1100 | 900 | 300 | 780 | 250 | 142 | 3+3 | 500 | 800 | 330 | - | 400 | 160 | 25 | 1000 | 30° | 2 |

| ST-8 | 1250 | 950 | 300 | 900 | 250 | 142 | 3+3 | 800 | 1200 | 380 | - | 500 | 160 | 30 | 1250 | 30° | 2 |

| ST-15 | 1420 | 1070 | 370 | 1100 | 300 | 180 | 3+3 | 1500 | 2000 | 420 | - | 500 | 200 | 55 | 1600 | 30° | 4 |

| ST-30 | 1740 | 1400 | 370 | 1100 | 300 | 180 | 4+4 | 3000 | 4000 | 570 | - | 985 | 160 | 75 | 2300 | 30° | 3 |

| ST-35 | 2030 | 1500 | 485 | 1800 | 300 | 225 | 4+4 | 3500 | 4000 | 750 | 53.7 | 23.5/14.7 | 220 | 35 | 4723 | 30° | 2/3.2 |

| ST-60 | 2467 | 1950 | 549 | 1700 | 300-400 | 240 | 5+5 | 6000 | 7000 | 1350 | 53.7 | 43.7/22.7 | 220 | 55 | 8330 | 30° | 2/3.7 |

| ST-80 | 2783 | 2265 | 548 | 1800 | 400-450 | 255 | 8+8 | 8000 | 9500 | 1830 | 53.7 | 46.6/27.6 | 300 | 82 | 11700 | 30° | 2.8/4.7 |

| ST-100 | 3800 | 3200 | 600 | 1700 | 400-500 | 280 | 9+9 | 10000 | 11300 | 2350 | 53.7 | 55.8/32.6 | 350 | 100 | 14800 | 30° | 3/5.1 |

| ST-120 | 3282 | 2575 | 720 | 2000 | 400-600 | 345 | 9+9 | 12000 | 15000 | 2950 | 54 | 76.6/44.8 | 350 | 124 | 22500 | 30° | 2.9/4.9 |

| ST-150 | 3666 | 2923 | 753 | 2000 | 500-800 | 360 | 8+8 | 15000 | 18000 | 3300 | 53.7 | 79.5/46.7 | 350 | 140 | 24000 | 30° | 3.2/5.5 |

| ST-200 | 4065 | 3323 | 786 | 500-800 | 375 | 8+8 | 20000 | 25000 | 4300 | 48 | 146.5/95 | 350 | 220 | 38000 | 30° | 3.5/5.4 | |

| ST-300 | 4530 | 3730 | 836 | 500-800 | 405 |

9+9 |

30000 | 37000 | 6500 | 66.4 | 173/101 | 330 | 260 | 59000 | 30° | 2.5/4.6 | |

| ST-400 | 4888 | 4090 | 880 | 500-800 | 420 | 10+10 | 40000 | 48000 | 7100 | 70.1 | 185/114 | 350 | 290 | 72800 | 30° | 2.3/4.3 |

Ningbo Kemer Engineering Machinery Co.,Ltd